While this article was written back in 2016 it gives and insight into the thinking that had been going on up to that time with respect to using ammonia as a fuel in combustion engines. Since then there has been a strong level of interest shown by the marine industry for the use of ammonia to power large scale marine engines. From what I have read so far I can why this would be based on comments from Caterpillars 2008 patent application which stated “When ammonia is combusted, the combustion produces a flame with a relatively low propagation speed . . . This low combustion rate of ammonia causes combustion to be inconsistent under low engine load and/or high engine speed operating conditions. “

Here is the article in full;

Ammonia energy proponents look forward to the day when their fuel is used in internal combustion engines – but the state of this art is unsettled and it is not clear which combustion technologies will win in the end.

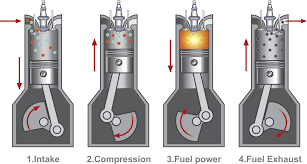

This lack of clarity notwithstanding, consensus prevails about the technical challenges that an ammonia engine must overcome. The Caterpillar Corporation put it succinctly in their 2008 patent application that covers a “power system having an ammonia-fueled engine”: “When ammonia is combusted, the combustion produces a flame with a relatively low propagation speed . . . This low combustion rate of ammonia causes combustion to be inconsistent under low engine load and/or high engine speed operating conditions. Most existing combustion engines that use ammonia as engine fuel typically require a combustion promoter (i.e.., a second fuel such as gasoline, hydrogen, diesel, etc.) for ignition, operation at low engine loads and/or high engine speed.”

In other words, one option is to use a liquid combustion promoter. However, as the patent subsequently notes, this approach “generally requires dual fuel storage systems, dual delivery systems, and dual injection systems, thus adding additional weight, complexity, and cost to the engine system.”

The second option is to use hydrogen as the combustion promoter. A promising variant of this approach is to place an on-board reformer between the fuel tank and the engine. The reformer can be set up to “crack” enough of the ammonia into hydrogen and nitrogen to support viable combustion. Crackers can be simple in mechanical terms, consisting of a heated chamber furnished internally with a catalyst. However, the patent describes one more challenge: “The requirement for the combustion promoter fuel fluctuates with varying engine loads and engine speed, which can cause control issues.” This means that cracking a fixed proportion of the ammonia (or a proportion that varies simply with the rate of fuel flow) is unlikely to produce good engine function.

Ammonia Energy has assembled data on nine current and recent ICE development programs. They are about evenly distributed across three camps.

First there are the carbon-based dual-fuel players working with spark-ignition systems. These include Bigas International and the SAVIA coalition of Italy; the Green Transportation Technology Group at the Korean Institute for Energy Research; and the ammonia research group at Xiamen University in China.

Next there are the carbon-based dual-fuel players working with compression-ignition systems. These include Sturman Industries (whose ALL-ternative engine was recently profiled by AmmoniaEnergy); Hydrofuel Inc. of Canada; and Song-Charng Kong’s program at Iowa State University. Caterpillar’s patent implies the use of a secondary fuel that is not hydrogen, but is silent on which ignition method might be employed.

Finally, there are the players who are using hydrogen as the combustion promoter. These include Toyota’s Central R&D Labs; and the Hydrogen Engine Center of Iowa in the U.S.

Based on the identity of the players and level of activity in each quadrant it is not obvious which approach is likely to win over the long run. One observation that can be made, though, is that most of the players in the top quadrants have stated plans to migrate away from fossil fuels as combustion promoters. This may involve “dropping in” a sustainable version of the secondary fuel, such as biodiesel. Or it may involve migrating from a fossil fuel to a different fuel that can be produced sustainably, such as dimethyl ether (DME). Or it may involve exiting carbon-based secondary fuels altogether and migrating into NH3/H2 quadrant.

Stephen H. Crolius followed up this article in 2020 with updates on how the future of ammonia as a fuel was looking.

He has this to say:

By Stephen H. Crolius on March 23, 2020

The diesel engine, also known as the compression ignition (CI) engine, has been a workhorse of the modern energy economy for more than a hundred years. Its role in the coming sustainable energy economy will be determined by its ability to co-evolve with climate-friendly fuels. Two researchers from the National Institute of Advanced Industrial Science and Technology in Japan have now examined the fit between ammonia and the CI engine. Pavlos Dimitriou and Rahat Javaid arrive at a two-part conclusion in their paper, “A review of ammonia as a compression ignition engine fuel,” published in January in the International Journal of Hydrogen Energy. Part one is good news: “Ammonia as a compression ignition fuel can be currently seen as a feasible solution.” Part two is a dose of qualifying reality: to manage emissions of N2O, NOx, and unburnt NH3, “after treatment systems are mandatory for the adaptation of this technology,” which means that ammonia-fueled CI engines are likely to be feasible “only for marine, power generation and possibly heavy-duty applications where no significant space constraints exist.”

The paper provides a detailed and readable account of efforts over the last eight decades to develop a viable version of an ammonia-fueled CI engine. The authors state that, “to the best of [their] knowledge, this is the first review approach focusing entirely on ammonia utilisation for compression ignition.” A major challenge confronted by the development efforts derives from ammonia’s “poor combustion characteristics … such as high auto ignition temperature, low flame speed, narrow flammability limits and high heat of vaporization.” They continue, “successful ammonia compression ignition operation could only be observed for engine designs that featured extremely high compression ratios from 35:1 to 100:1.”

To address this challenge, most researchers resorted to the expedient of co-combustion. With the addition of fuels like diesel, biodiesel, and dimethyl ether, “the combustion of ammonia … is a realistic conception, as the secondary fuel, with lower Auto ignition temperature, can be used to trigger the combustion of the mixture.” Different researchers have used a variety of fuel ratios under a variety of conditions. Ammonia ratios as high as 95% have been achieved, but numbers in the range of 40 to 80% are more prevalent in the literature. Hydrogen has been used successfully as the complementary fuel. This includes hydrogen derived from on-board ammonia cracking, but the authors of one study determined that “the introduction of pure hydrogen [from an off-board source] seems to be the most promising in terms of emissions reduction and engine performance enhancement.”

The dual-fuel approach opens the door to CI for ammonia, but another challenge soon arises: when ammonia is burned as a CI fuel, it tends to produce problematic levels of nitrogen oxides and unburned ammonia. To compound the issue, NOx tends to be a product of high combustion temperatures and unburned ammonia of low temperatures – and there is no “sweet spot” temperature where neither species is a problem.

Contemporary researchers are attacking this problem with two methods. The first is with advanced fuel injection techniques. By injecting fuel at several points during the engine’s compression stroke, with fine control of the fuel increments, it is possible to achieve “simultaneous reduction of N2O and NH3 emissions in ammonia dual-fuel engines.” The second method is exhaust after-treatment. Selective catalytic reduction (SCR) technologies have been found that can reduce both NOx and unburned ammonia to acceptable levels, a result furthered by “the effect of ammonia in NOx reduction as observed in the modern after-treatment systems.”

The authors’ conclusion that ammonia is unlikely to become a major fuel for passenger cars will not come as a surprise to most members of the ammonia energy community. Ships, of course, are a different story.

Engine manufacturer MAN Energy Solutions expects to bring its dual-fueled maritime engine to market in 2024. (An Ammonia Energy update on the MAN ammonia engine appeared in January.) Success in the maritime realm will certainly encourage development of engines scaled for off-grid and back-up power generation. For other transportation applications, long the near-exclusive province of internal combustion, CI might have its hands full fighting off electrification via battery and fuel cell.